Category Archives: BPU

Electronic boost controllers(ebc) photos

Greddy bcc install & tune

GREDDY BCC –

INSTALL & TUNE

I.

Introduction to the Greddy Boost Cut Controller (BCC) :As the turbo pressure sensor

(TPS) on the TT Supra sees increase boost, help it sends an increased voltage

(V) on to the ECU. When typical stock boost level is exceeded, the higher TPS V

signal causes the ECU to invoke Fuel Cut; this prohibits excess boost.

The BCC is simply placed in the middle of this wire from the TPS to the ECU.

At peak-stock and lower boost levels, the BCC passes unaltered stock V

signals on to the ECU. As stock boost levels are exceeded, the BCC inputs

the too-high V signal from the TPS, but limits its output V to the ECU to

peak-stock level. Fuel cut is now not invoked at over-stock boost.Note that Greddy does not

list a BCC as made for the 93-98 Supra TT. The correct Greddy BCC to use

is labeled for the '90-'96 MR-2 Turbo, Greddy part # 15510006II.

BCC Wiring Clarification and Notes:The TPS to ECU wire is Black

with two Yellow stripes located on the larger ecu

harness. This wire is cut; the resulting cut end that goes to the TPS

connects to the BCC White input wire. The other cut end that goes

to the ECU connects to the BCC Green output wire. Most people have

cut the Blk/Ylw wire near the ECU; note that alternatively the same wire

can be found inside the wiring loom along the top/back of the engine bay.

This “away from ECU” access option is detailed in Part IV below.The BCC's Red wire

may be connected to Any ignition/switched 12V source. Therefore, it is not

necessary to cut an ECU wire for this as described in the “BCC

Install” article, although you may choose to. Other options include

access at the unused seat-heater fuse slot in the top row of the fusebox near

driver's left foot.The BCC's black wire

is connected to Any quality ground. Again, it is not necessary to cut an

ECU wire to simply ground the BCC. Other options include crimping to a

ring connector, secured firmly under a chassis bolt cleaned of paint or debris.With these connections made,

you can choose to place the BCC device itself near the ECU, under the dash, or

near the interior fuse box. One senior lister has even placed the BCC

inside the ECU .

Fields Harness Option: ( DISCONTINUED

)

Field's One Touch Replacement Harness at

www.MVPmotorsports.com

: This product is placed between the

stock male/female ECU wiring harness, to allow access without cutting any wires. Making room for this Harness also calls for

re-positioning or removing the Trac ECU (adjacent to Main ECU).

III.

Precision Adjustment of the BCC Output Voltage:Inside the BCC shell is a

screw that providesadjustment of the peak voltage output. Since the ECU

uses the TPS V data for many functions, you want this set only as low as needed

to avoid fuel cut, and not unnecessarily lower. The setting as it comes

from Greddy is usable but lower than necessary, and varies from unit to unit.

You could roughly set it by just repeatedly driving your car at max boost and

slowly turning the screw counterclockwise

to reduce the peak voltage output

until you no longer hit fuel cut. But this is a crude method compared to

adjusting it precisely by measurement with a volt meter, as follows:1.

The Connections for Voltage Tune assume your BCC is uninstalled. To Volt

tune after the BCC is fully installed, you will need to disconnect the BCC's

green and white wires to proceed, but may leave the red and black wires

installed.2.

Red BCC wire to any 12V source such as car battery +3.

Black BCC wire, and negative probe of your voltmeter, to ground of same battery.4. White

BCC wire to any automotive voltage source of 5-12V. Simplest is to

use the 12V source same as red wire. Others have used the 6V output of a

battery charger, doesn't matter because any Input of 5-12v to the BCC will give

the same Output for a given adjustment screw setting.5.

Green BCC wire to the positive probe of your voltmeter.6.

Turn screw to provide voltmeter reading of Nearly but Not More Than:

4.3 V for 93-95 cars; 4.1 V for 96-98 cars.IV.

Alternative Access of TPS to ECU wire, Away from ECU – DetailsFind the turbo

pressure sensor about 2/3 way back along top of engine intake area. It

has 3 wires coming out of it. The middle one is the Black with two Yellow stripe

wire. Now you know what the target wire looks like. Remove the top

plastic cover from the big wiring loom that runs along the back/top of the

engine bay/fire wall. The clips on this cover are a PITA to get off – use

two small screw drivers and be patient. At the driver end of the uncovered

wire loom, undo the broad electrical tape so you can SPREAD OUT and look

at EVERY individual wire. Be careful, some colors like tan, beige etc

look similar to yellow stripes. Use a bright light and look at ALL

the wires and you will find each is unique. There are Two different

wires that are both black with yellow stripes, but one is clearly bigger

around/larger gauge wire. The smaller diameter/gauge wire is the one you

want, compare it to the end you can see at the TPS. Only when you are

certian that you have identified the only correct wire, cut it. You can

then confirm it is correct by using your voltmeter set for resistance to look

for continuity between the wire you cut and the middle wire on the unplugged end

of the TPS. The end of the cut wire heading toward driver end of loom is

the TPS end for white BCC; the end toward passenger end of loom is the ECU end

for green Bcc. Pull your extension wire leads from the BCC through the

firewall passage from the interior inside by the clutch pedal, details about

this are also on boost gauge tech article. Crimp your BCC leads on to your

cut wire at the loom. Wrap your loom back up, snap the cover back on, you're

done.

Next to the

Greddy BCC install with Photos

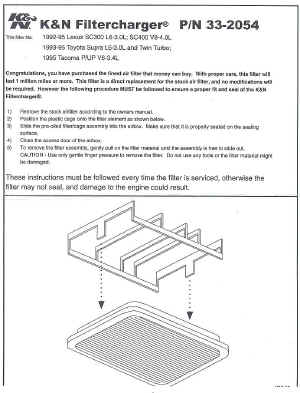

Custom fitted apex'i air filter

Custom Fitted

Apexi Air Filter

— Install

—

Check these Test

Results to find out why this cone filter is the “Best” for your Supra!

The New Cone

%10 better flow

Filter with gasket, sickness 3″ toilet flange, try and 3″ rubber pipe flared at both ends.

I cut off one of the ends of the flared pipes to fit onto the flange.

Estimated cost of accessories was approx $17 at local plumbing store.

Dremmeled flange to fit on the filter, buy

attached flange with gasket onto filter with 4 bolts supplied.

Attached cut end of 3″ hose to flange and filter with cl

amp that was provided on the rubber hose.

Finished product

Another angle of the finished product. This mod took approx 45 minutes and was rather easy to accomplish. Filter works great.

The Old Cone

(almost the same as the new design)

Comments/suggestions? Email

me

![]()

Downpipe installation

RMM Downpipe Installation

|

1

All filters were tested on a modified |

![]()

![h5[1].jpg (61691 bytes)](https://i0.wp.com/www.mkiv.com/techarticles/ebc/h51_small.jpg?resize=200%2C133)

![mvc-904f[1].jpg (24525 bytes)](https://i0.wp.com/www.mkiv.com/techarticles/ebc/mvc-904f1_small.jpg?resize=200%2C138)

![avcr[1].jpg (62051 bytes)](https://i0.wp.com/www.mkiv.com/techarticles/ebc/avcr1_small.jpg?resize=200%2C133)

![interior[1].jpg (83180 bytes)](https://i0.wp.com/www.mkiv.com/techarticles/ebc/interior1_small.jpg?resize=200%2C150)